Why Is Stormwater Management Important?

Stormwater is just rain or meltwater and is not the most pressing issue on many peoples’ minds as they do their daily work. That is… until there’s more stormwater at their feet than the ground can absorb, and more stormwater than the rivers can carry. Once people are facing a flood at their very own feet or in their community, then stormwater becomes very important. And, of course, when a flood happens, there is not much to do but wait for the water to recede.

Stormwater is just rain or meltwater and is not the most pressing issue on many peoples’ minds as they do their daily work. That is… until there’s more stormwater at their feet than the ground can absorb, and more stormwater than the rivers can carry. Once people are facing a flood at their very own feet or in their community, then stormwater becomes very important. And, of course, when a flood happens, there is not much to do but wait for the water to recede.

Why Does Land Development Increase the Need for Stormwater Management?

Land development is good for the economic growth of a region. However, with land development comes fewer pervious surfaces. Therefore, stormwater has less surface area where it can soak into the ground. Impervious surfaces can include things like a roof of a building, a road, or a parking lot. Therefore, land development results in a need for stormwater management.

Stormwater Management Options for Land Developers

Three examples of options for stormwater management include (but are not limited to):

- surface basins – an area where water can be directed from a developed area, creating a temporary pond, until the water can soak into the ground;

- permeable pavement – an alternative to traditional asphalt paving, which allows water to pass through the surface and infiltrate into the ground under the pavement; and

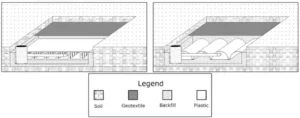

- lastly, recharge chambers or underground stormwater infiltration basins – a structure, typically made of concrete arches or a modular plastic framework, built under a parking lot, stadium, or another impervious surface to hold stormwater until it can soak into the ground.

Assessing the Life Cycle Impact of Recharge Chambers

Recent research work with colleagues I met at Drexel University focused on assessing the life cycle impact of recharge chambers. We investigated the environmental midpoint impact assessment metrics of:

- acidification;

- eutrophication;

- global warming; and

- fossil fuel resources.

These four metrics were chosen since they all pertain to water resources or infrastructure development.

Taking a Life Cycle Approach to Evaluate Stormwater Management Projects

Using a life cycle approach to evaluate projects means that cradle-to-grave impacts are considered, not just one life cycle phase. A life cycle approach means we consider all inputs from nature, through manufacturing, transportation, use, maintenance, repair, recycling, and finally end-of-life. Earlier research compared the cradle-to-grave potential impact of various stormwater management solutions, finding that the cradle-to-installation phase of the recharge chambers dominated the cradle-to-grave life cycle impact. Said another way, the use and end-of-life phases were small compared to the manufacturing and installation phases.

The earlier research led to further studies, explicitly comparing many different manufacturers’ plastic recharge chambers through the manufacturing and installation phases. Results from this work revealed significant differences in these plastic recharge chambers.

Type of Plastic Used (polypropylene, polyvinyl chloride, recycled polypropylene)

The plastic materials used in the recharge chamber design can represent as much as 99% of the cradle-to-installation environmental midpoint impact of the recharge chamber. Additionally,

Manufacturing Process Used to Make the Plastic Components (injection molding, thermoforming, extruding)

When manufacturers use injection molding to make the plastic components, the process can create an impact of about 50% higher than if they extrude the material. In addition, the impact of injection molding is also higher than if the material is thermoformed.

Type of Backfill Material Used During Installation (sand, gravel)

The processing and transporting of backfill materials, specifically sand or gravel, to the project site can be approximately 20% of the total cradle-to-installation impact, with sand being a better choice than gravel if transported the same distance. And finally, this work revealed that the transport distance for these backfill materials is highly significant. The transportation impact can exceed plastic when transport distances become very long. Using gravel, where the closest quarry is nearby, is preferred to using sand, where the nearest source of sand is hundreds of miles away.

Conclusion Regarding Recharge Chambers for Stormwater Management

In conclusion, recharge chambers produce potential environmental midpoint impacts that are less favorable than some other stormwater management infrastructure solutions. However, they play an essential role in providing flood protection. Municipalities and developers commonly use recharge chambers in projects where limited land area prevents use of other stormwater management approaches. For more information about this research on the life cycle assessment of recharge chambers, please refer to the published paper

Life Cycle Environmental Impact of Underground Plastic Recharge Chambers in Stormwater Management

In early 2022, the US

In early 2022, the US

The Order of the Engineer inducted Lisa A. Peterson on September 25, 2020. According to

The Order of the Engineer inducted Lisa A. Peterson on September 25, 2020. According to